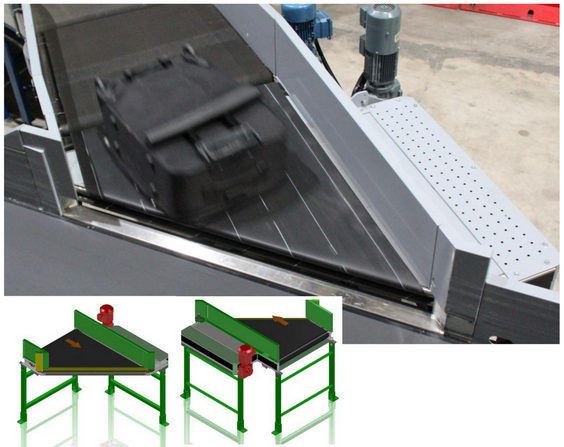

FEATURES

For Merging & Diverting Operation Robust and reliable Low vibration Low noise Integrated Electrical Trunking System

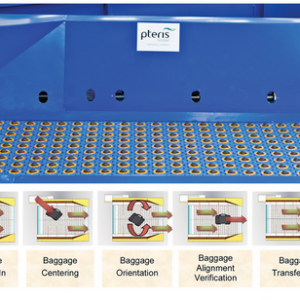

SYSTEM HIGHLIGHTS

|

|

TECHNICAL SPECIFICATIONS

| Effective Width W0 | 1000 mm |

| Effective Length L0 | 1000 mm |

| External Dimension D1 | 361 mm |

| External Dimension D2 | 1566 mm |

| External Dimension D3 | 1616 mm |

| External Dimension D4 | 1712 mm |

| Height (Body Frame) | 185 mmW |

| Safeguard Height | 300 mm |

| Conveyor Belt Material | 2 ? ply polyester, PVC Black, Low Friction Fabrics |

| Belt Speed | Up to 2.0 m/s |

| Drive Motor Power | 1.5kW-2.2 kW |

| Load Capacity | 60 kg |

| * Above dimensions are standard and can be customized to requirement * Voltage can be adapted to local requirement |